| 400°C | HEAT RESISTANT |

| PTFE | MICROPOWDER |

| KT/KTL | SERIES |

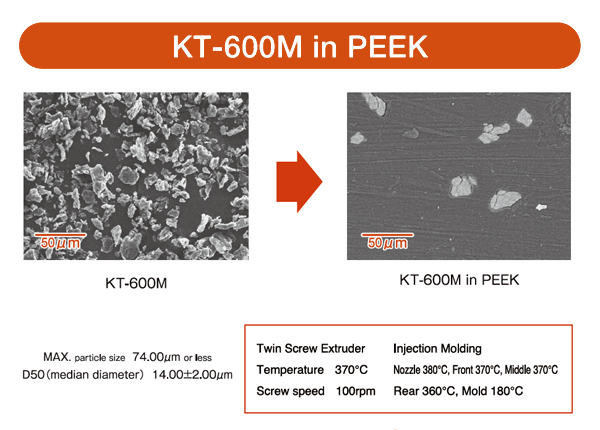

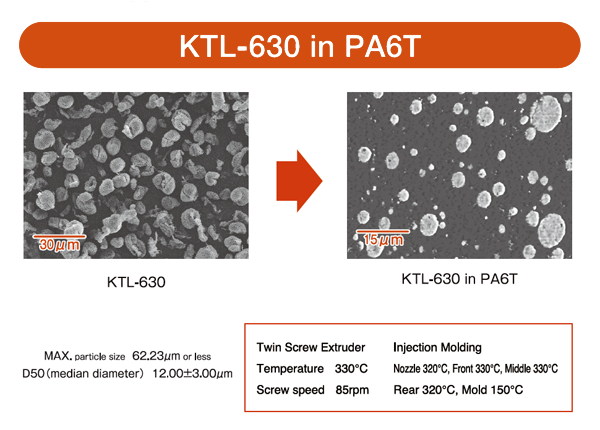

The KT/KTL series are PTFE (polytetrafluoroethylene) micropowders which provide low-friction and wear-resistance.

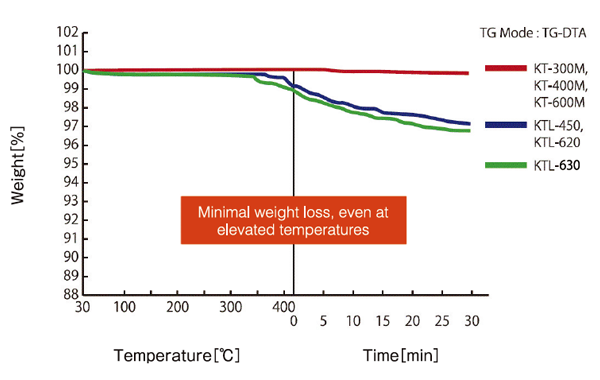

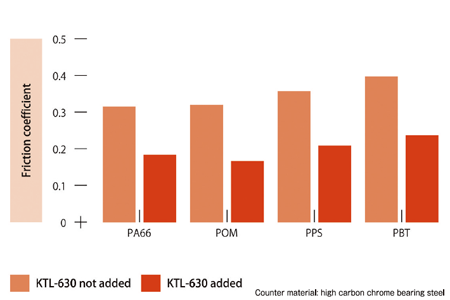

The KT/KTL series drastically reduce the friction coefficient and wear, and improve the PV value when added to thermoplastics and thermosetting plastics, rubbers, elastomers. Also the KT/KTL series can add performances such as stain-resistance, non-stick, water/oil repellency.

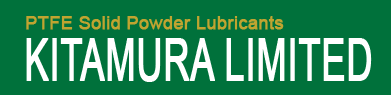

The KT/KTL series(especially, the high molecular weight grades of KT series) do not flow or thermally decompose at temperatures above the melting point. Therefore they can be added to every kinds of plastics molded over 400°C.

Features

TG-chart(increase by 10°C/min. up to 420°C, then hold at 30min)

Various plastics+KTL-630(10wt.%) Friction coefficient

PPS+KTL-630(10wt.%) Specific wear amount

Uses

KT/KTL Series for Plastic Compounding

| KT series | Features |

Fine powder of completely sintered the highest-molecular-weight and the highest heat-resistant PTFE. Not thermally decomposed at 420°C, also the best for POM which is not good at acidic gas. Does not flow at temperatures at and over the melting point, retaining uniform dispersion at high temperatures. |

| Applications |

Every kinds of thermoplastics and thermosetting plastics (including POM), Rubbers, Elastomers |

| KTL-450A KTL-450 KTL-620 |

Features |

Fine powder of completely sintered high-molecular-weight PTFE. Excellent flow and dispersion characteristics. Can be fed into kneaders directly by side feeding. Minute mass or shape change around the melting point, contributing to high stability in mold strength and size. |

| Applications |

Plastics (processing temperature : over 350°C), Rubbers, Elastomers (PEEK, Aromatic PA, PES, Thermoplastic PI, PEI, PAI etc.) |

| KTL-630 | Features |

Refer to KTL-450A, KTL-450, KTL620 |

| Applications |

Plastics (processing temperature : less 350°C), Rubbers, Elastomers (PPS, PA, PBT, PC, General plastics etc.) |

Applications

Additives for Synthetic Resins

Additives for Synthetic Resins

Additives for Rubber and Elastomers